Capabilities – Advanced PCB Assembly

Advanced PCB Assembly

Advanced PCB Assembly

To optimize customers’ expectations on both product performance and ROI of their applications, Vayu will provide PCB fabrication and assembly service under one roof. With Certification by ISO9001, TS16949, UL and RoHS, we will have obtained sufficient high PCB assembly capabilities to provide high quality assembly services under highly rigorous quality standards and regulations.

We will offer custom circuit assembly services ranging from prototype PCB assembly, low-to-mid volume PCB assembly to high volume PCB assembly. We’re capable of providing RoHS-compliant assembly and non-RoHS assembly to conformal coating based on your custom needs.

| PCBs We Can Assemble |

| √ Min size: PCB whose width/length is less than 30mm should be panelized √ Max size: single board 500mm*400mm | panel board 310mm*410mm √ Layer Count: 1-40 layers (1-20 layers for mass production) √ Copper Thickness: 1oz – 15oz √ PCB Types: Rigid PCBs, Flex PCBs, Rigid Flex PCBs, MCPCBs, Rogers PCBs, Ceramic PCBs, etc. √ Surface Finishes: Lead/Lead-free HASL, ENIG, ImSilver, OSP, Gold plated. |

| Components We Can Assemble |

| √ SMT sizes: 01005, 0201 or larger √ Fine pitch: 0.4mm or greater √ BGA pitch: 0.35mm or greater √ BGA Ball count: 2 – 50 √ WLCSP pitch: 0.35mm or greater √ BGA, micro-BGA, POP, CSP, LGA package, Flip chip, Hard metric connectors, Cable & wire, etc. √ Components Height: 0.1mm – 12mm √ Min. Components Spacing: 0.20mm for SMT parts, no specific demand for Thru-hole parts |

| SMT Component Presentation |

| √ Bulk √ Cut Tape √ Tube √ Tray √ Partial Reel and Full Reel |

| Custom PCB Assembly Capabilities |

| √ Quick Turn √ Prototype Quantities to Production Quantities √ IPC III standard compliant √ Single PCB Assembly and PCB Panel Assembly √ Single and Double-sided PCB Assembly √ SMT Assembly, Thru-hole Assembly, and Combo of SMT and Thru-hole Assembly √ Leaded Assembly, Lead-free or RoHS Compliant Assembly and No-clean Process Assembly √ Consigned PCB Assembly, Partial consigned PCB Assembly and Full turnkey PCB Assembly |

| Advanced PCB Assembly Options: √ Box build assembly √ Comprehensive Components Sourcing Service (purchased from authorized distributors only) √ IC Programming |

| Value-added / Special Services We Offer |

| √ Free Stencil √ Free DFM and DFA Check √ Free Tips to Reduce Assembly Cost (components cost-down, alternative recommendation, etc.) √ Free PCB Panelization Service √ Free Automated Optical Inspection (AOI) √ Automated X-ray Inspection (AXI) √ Electrical Test (including flying probe test) And Custom Test Requirements √ First Article Inspection √ Expedited PCB Production Service √ Excellent Customer Service to Meet Your Special Demands |

Note: 1mm=39.37mil, 1mm=0.03937inch, 1oz=35μm.

Assembly Equipments

At Vayu, we pride ourselves on being a full-service, turnkey solution that can not only help you with the design and manufacture of your printed circuit boards, but also take you all the way through the assembly process. We can do that due to our significant investment in the best PCB assembly equipment we can find.

You’ll enjoy high-quality PCB fabrication and assembly services from Vayu due to our rigorous PCB manufacturing standards, regulations in manufacturing processes and our PCB assembly equipment’s high degree of accuracy. Our PCB assembly process adheres to manufacturing requirements of IPC-610D, JSTD-020C, JSTD-005 and JSTD22-B117. Some equipment is shown in the table below.

| Equipment Function | Model | Features |

| Solder paste printing | G5 | Accuracy: ±0.025mm Max. speed: 150mm/sec PCB max. area: 400*310mm PCB thickness: 0.2-6mm |

| Surface mount placement | SM421 | Accuracy: ±0.03mm Speed: 0.17sec/pc PCB max. area: 600*400mm Available part: 0201 chip to 35*35mm |

| SM471 | Accuracy: ±0.05mm Speed: 0.048sec/pc PCB max. area: 510*640mm Available part: 0402 chips to 14mm(H 12mm) | |

| NPM-W2 | Placement accuracy(Cpk1): ±0.04 mm for 0402, 0603, 1005 chips; ±0.03 mm for 03015, 0402, 0603, 1005 chips; Max. speed: 0.094s/chip PCB max. area: 750*550mm Component dimensions (mm): 03015 chip ~ 6*6(H 3mm); 0402 chip ~ 12*12(H 6.5mm); 0603 chip ~ 120*90 or 150*25(H 30mm) | |

| Reflow | NS800II | Nitrogen source: external PCB max. size: 400mm Temperature accuracy: ±4°C Zones: 8 Lead free compatible |

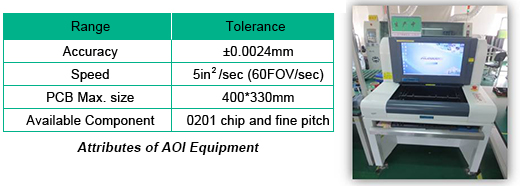

| AOI | ALD515 | Accuracy: ±0.0024mm Speed: 5in² /sec (60FOV/sec) PCB max. area: 400*330mm Available component: 0201 chip and fine pitch |

| V-cutting | 400 | Accuracy: ±0.25mm PCB max. size: 400mm |

| Cleaning | FR-1054 | PCB max. area: 400*300mm |

| X-ray inspection | VIEW X2000 | BGA void Solderability inner shielding |

| BGA rework | ZM-R6810 | Nitrogen source: NA PCB max. size: 350mm Temperature accuracy: ±1°C Lead free compatible |

| Wave solder | GSD-WD300T | Nitrogen source: external PCB max. size: 400mm Temperature accuracy: ±1°C Lead free compatible |

| JADE MK II | PCB max. size: 457*508mm Applicators: 1.5 ~ 25mm Solder: Most commonly used solder types – including lead-free Repeatability: ±0.05mm | |

| 3DSPI | InSPIre 510B | PCB max. size: 510*505mm (board);480*490mm (inspection area) Inspection Items: volume, area, height, X-Y offest, shape Defects: missing, bridging, excess/insufficient solder Minimum component: 01005 |

Types of Equipment Vayu Uses for PCB Assembly:

Our PCB assembly equipment includes machines for AOI, BGA rework, cleaning, reflow, solder paste printing, surface mount placement, V-cutting, wave solder and X-ray inspection. Because we only use state-of-the-art PCB assembly equipment, we can design our printed circuit boards to your specifications with a very high degree of accuracy, even at higher or lower than standard temperatures.

Variety when it comes to shape, type of material, size or other special PCB needs is no problem for our technicians or the equipment they have at their disposal for printed circuit board assembly.

How Can Vayu Help With Your Custom design?

Thanks to these modern assembly machines, you’ll enjoy high-quality printed circuit boards from Vayu. We specialize in offering a variety of useful services for your printed circuit board assembly, including:

• RoHS compliant lead-free assembly

• Non-RoHS assembly

• Conformal coating

• Prototype assembly

• Low-volume assembly

• Consigned assembly

• Full turnkey assembly

Our complete range of assembly services means we can almost certainly meet the PCB assembly needs of your particular company, which in turn means you won’t have to look elsewhere for the assembly of your printed circuit boards, saving you valuable time, money and logistical issues.

Is Vayu Printed Circuit Board Assembly good for your product/device?

Companies that specialize in printed circuit board design or manufacture often don’t do PCB assembly at all. Those that do may offer it as an afterthought, an extra service they don’t necessarily dedicate a lot of resources to. This means you may not get the best or the fastest assembly possible for the price.

If you take your board to a company that specializes in design, you may get a quality plan, but you will have to deal with the logistics and time lost in getting your boards to the new company for assembly, to say nothing of the extra cost.

Using Vayu means you have a one-stop shop for your PCB project. We have the resources to give you a great design, manufacture and assembly. So, you save time, money and hassle without worrying about any loss in the quality of your project by letting Vayu take care of everything for you.

Let Vayu Put Our Top-of-the-Line PCB Assembly Equipment to work for you.

SMT Packages

Surface Mount Technology (SMT): The technology of processing bare PCB boards and mounting electronic components on the PCB board. This is the more popular electronic processing technology nowadays, because electronic components are getting smaller and smaller, and there is a trend to gradually replace DIP plug-in technology.

The SMT process can be divided into pre-process and in-process. Before it starts, various PCB documents, such as circuit board data (Gerber), bill of materials (BOM), and auxiliary data, etc. need to be prepared, which are the basis of SMT technology processing. After the preparation work is fully completed, it will be carried out.

We provide one-stop solutions including PCB fabrication, components procurement and PCB Assembly services. Owing to stringent manufacturing rules and regulations, increasing technological knowledge and enthusiasm to strive for the latest technologies, we have accumulated numerous capabilities to deal with different SMT package type such as BGA, PBGA, Flip chip, CSP and WLCSP.

BGA

BGA, short for ball grid array, is a form of SMT package that is increasingly used in integrated circuits. BGA is beneficial to the improvement of solder joint reliability.

BGA exhibits the following advantages:

• Efficient application of PCB space – BGA package places connections beneath SMD (Surface Mount Device) package instead of around it so that space can be largely saved.

• Improvement in terms of thermal and electrical performance – Since BGA package helps to reduce inductance of power and ground planes and impedance controlled signal lines, heat can be moved away from pad, beneficial to heat dissipation.

• Increase of manufacturing yields – Owing to progress of solder reliability, BGA can maintain relatively large space between connections and high-quality soldering.

• Package thickness reduction – We specialize in handling fine pitch components assembly and up to now we can deal with BGAs whose minimum pitch can be as small as 0.35mm.

When you place a full turn-key PCB assembly order concerning BGA package, our engineers will, first of all, check your PCB files and BGA datasheet to summarize a thermal profile in which elements have to be taken into consideration such as BGA size, ball material etc. Prior to this step, we will check your PCB design for BGA and provide a Free DFM check to be aware of elements essential to PCB assembly including substrate material, surface finish, soldermask clearance, etc.

Due to attributes of BGA package, Automated Optical Inspection (AOI) fails to meet the inspection needs. We undertake BGA inspection by Automated X-ray Inspection (AXI) equipment capable of inspecting soldering defects at the early stage prior to volume manufacturing.

PBGA

PBGA (Plastic Ball Grid Array), is a popular packaging form for medium-high level I/O devices. Depending on laminate substrate contains extra copper layers inside, it is good to heat dissipation and can cater to larger body sizes & number of balls to meet a wider range of needs. Its advantages include:

• Requiring low inductance

• Making surface mount easier

• Relatively low cost

• Maintaining relatively high reliability

• Reducing coplanar issues

• Obtaining relatively high-level thermal and electrical performance

Flip chip

As a method of electrical connection, flip chip connects die and package substrate by directly facing down IC in order to make it attached to substrate, circuit board or carrier. Merits of flip chip include:

• Reducing signal inductance and power/ground inductanc

• Decreasing the number of package pins and size of die

• Increasing signal density

CSP and WLCSP

Up to now, CSP is the latest form of package, short for chip scale package. As the description its name indicates, CSP refers to a package whose size is similar to that of a chip with defects concerning bare chips eliminated. CSP provides a packaging solution that is denser and easier, cheaper and faster. And the following features of CSP helps lead to increasing of assembly yields and lower manufacturing cost.

CSP is so popular and efficient in this industry that up to now there are over 50 types of CSPs in its family and the number is still growing every day. A lot of attributes and features of CSP are contributive to its wide popularity in this field:

• Reduction of package size – It can obtain a packaging efficiency higher than 83%, largely increasing density of products.

• Self alignment – It can be self aligned during PCB assembly reflow so that it makes SMT easier.

• Lack of bent leads – Without participation of bent leads, coplanar issues can be greatly reduced.

WLCSP, short for wafer level chip scale package, is a real type of CSP since its finished package exhibits a chip-scale size. WLCSP refers to IC packaging technology at the wafer level. A device with WLCSP is actually a die on which an array of bumps or solder balls is arranged at an I/O pitch, meeting the requirements of traditional circuit board assembly processes. Its advantages primarily include:

• Inductance from die to PCB is the smallest;

• Package size is greatly reduced with density degree improved;

• Thermal conduction performance is tremendously enhanced.

Up to now, we are capable of dealing with WLCSP whose both minimum Within-Die pitch and Across-Die pitch can reach 0.35mm.

0201 and 01005

As electronic market and products advance, growing trend of miniaturization of cell phones, laptops etc. is constantly driving for components with smaller sizes. 0201 and 01005 are extremely popular in electronic market due to the following advantages:

• Tiny size making them quite welcome in space-constrained end products;

• Excellent performance in functionality enhancement of electronic products;

• Compatible with high density needs of modern electronic products;

• Very high-speed applications.

To achieve assembly capabilities of 01005, we’ve succeeded in dealing with aspects concerning its assembly process including PCB design, components, solder paste, pick and placement, reflow, stencil and inspection. Our experience helps us summarize that in terms of post-reflow issues, compared with components with other types of packages, components packaged with 01005 perform better in issue elimination such as bridging, tombstone, edge-standing, upside-down, missing part etc.

We are capable of handling more different types of packages in PCB assembly process. Click following button to submit your circuit spec and upload BOM for PCBA quote. If your required component package form isn’t mentioned above, please do not hesitate to send us a message for our expanded package handling capabilities.

Package on Package

When people are being asked for their long-standing demands for electronic products, they will reply the following key words without hemming or hawing: smaller, lighter, faster and more multi-functional. In order to lead modern electronic products to be compatible with those demands, advanced printed circuit board assembly technologies have been widely introduced and applied, among which PoP (Package on Package) technology has won millions of proponents.

Introduction of Package on Package:

Briefly speaking, Package on Package is actually a process of stacking components or ICs (Integrated Circuits) together on a motherboard. As an advancing packaging method, PoP allows multiple ICs to be integrated into a single package containing logic devices and memory devices in top package and bottom package, leading to increased memory density and performance and reduced mounted area. PoP can be classified into two structures: standard structure and TMV structure. The standard structure contains logic devices in bottom package while memory devices or stacked memories in top package. As an upgraded version of a PoP standard structure, TMV (Through Mold Via) structure implements its internal connection between logic devices and memory devices through mold via in bottom package.

When it comes to its surface mount assembly process, package on package involves two key technologies: pre-stacked PoP and on-board stacking PoP. The key difference between them lies in times of reflow soldering: the former through two-time reflowing while the latter one-time.

Advantages of Package on Package:

PoP technology is being widely applied by OEMs owing to its impressively advantages:

• Flexibility – Stacking structure of PoP provides OEMs such multiple selections of stacking that they are able to modify functions of their products at ease. For example, they are allowed to modify low-memory chip into high-memory chip to cater to newly-coming demands without need to change circuit board design of motherboard.

• Overall size reduction

• Shrinking overall cost

• Reducing motherboard complexity

• Improving logistics management

• Enhancing technology reuse level

Application Fields of Package on Package:

Attributes of PoP work perfectly on portable electronic products including phones, digital cameras, portable media players, portable digital assistants and other devices concerning gaming and music.

Vayu wil achieve on surface mount assembly, serving for various fields. Thanks to advanced technologies, rigorous manufacturing standards, up-to-date equipment and professional engineering staff, we will scale up to custom designed products.

Box Build Assembly

As a global Electronic Manufacturing Service (EMS) supplier, Vayu will play an active and competent role in the whole process from PCB production, component sourcing, PCB assemblies, and testing to electronic products packaging and shipping in order to focus on clients’ specific needs.

Box Build Assembly Services:

Box build assembly covers such a wide range of items that it differs each time when required by different people. It can be either as simple as putting electronic systems into simple enclosures with interfaces or displays or as complicated as system integrations containing thousands of individual components or sub assemblies. In one word, products after box build assembly can be directly sent for sale.

Box Build Assembly Capabilities:

Compatible with guidelines of ISO9001, IATF16949, RoHS and UL certificates, we offer turnkey and custom box build assembly products and services, including:

• Cable assemblies;

• Wiring harnesses;

• High level integration and assembly of high mix, high complexity products;

• Electro-mechanical assemblies;

• Low-cost and high-quality component sourcing;

• Environmental testing and functional test;

• Custom Packaging

PCB Assembly

Owing to our longstanding innovation and constant growing crafts, we provide turnkey PCB assembly and consignment PCB assembly services with high quality and short lead time. Our engineers and workers perform professionally and proficiently in terms of both thru-hole technology (THT) assembly and Surface Mount Technology (SMT) assembly.

Sourcing

More than a decade’s cooperative partnership with renowned and qualified component manufacturer allows us to be competent in component procurement at a high speed and competitive prices, which enables customers to quickly and reliably embrace their products.

Testing Solutions

Testing is a key element in judging the reliability of electronic products. We offer comprehensive testing and inspection solutions containing ICT, flying probe, Automated/Automatic Optical Inspection (AOI) test and Automated/Automatic X-ray Inspection (AXI) test so as to guarantee performance of products before leaving to plant.

Free DFM Check

As a value-added service contributing to our PCB Assembly services, we offer Free PCB File Check, also known as Free DFM, namely we help check your PCB design file for possible issues that may stop or hinder manufacturing. If any issues were detected, we would get in touch with you immediately to solve the issue together, then schedule the PCB fabrication accordingly.

In spite of no charge, the DFM Check provided by Vayu is 100% cost-effective because the Valor DFM/DFA check system we use is an automatic DFM/DFA check system capable of rapidly going over manufacturing issues that may prohibit PCB manufacturing process. Thus, the application of Valor DFM/DFA check is beneficial to your production as it lowers your PCB cost and saves PCB lead time.

Vayu carries out DFM from 5 aspects: Drill Checks, Signal and Mixed Layer Checks, Power/Ground Checks, Solder Mask Checks, Silkscreen Checks. We have specific PCB DFM checklists, sa shown below:

Drill Checks:

The Drill Checks action is intended to find potential manufacturability defects in drill layers (through, buried and blind via layers) and generate statistics on drill layers. It is intended to operate only on drill layers. It uses the drill layer, the top and bottom layers of its drill stack and any power or ground layer in the stack. The main checklist is displayed in below table.

| Check Items | Functions |

| Hole size | Provides a list of all PTHs, NPTHs & vias, and NPTHs that need pilot drills. |

| Hole separation | Reports duplicate holes, touching holes and close holes. |

| Missing holes | Reports missing drills for non-SMD pads. |

| Extra holes | Reports redundant drills that do not belong to any pad. |

| Power/ Ground shorts | Reports drills touching large copper nets of more than one power or ground layer. |

| NPTH to Route | Reports drills that have the Tooling hole or Mounting hole attributes, and NPTHs that are close to the route path. |

| Stubbed vias | Reports cases of vias not connected to at least two copper layers. |

| Thermal connection | Reports the absence of thermals for Thru-hole pin drills and calculates the total copper area of thermal connections through all negative power, ground and mixed layers. |

Signal and Mixed Layer Checks:

This function is intended to find potential manufacturability defects in Signal layers and mixed layers and generate statistics. The action can operate on any layer, but is mainly intended for signal layers. It uses the layer itself and any NC (drill or route) layer which pierces it. The main checklist is displayed in below table.

| Check Items | Functions |

| Spacing | Reports spacing violations between pads, circuits and nets, and between text to text, also shorts and spacing between different CAD nets & close distances between non-touching features on the same CAD or layer nets. |

| Drill | Reports distance violations between NPTHs/PTHs/Vias, and pads, circuits, annular rings and copper. Also reports missing pads. |

| Route | Reports distance violations between edge of route features and pads, circuits, etc. |

| Size | Reports size of pads, shaved lines, text, line neckdowns, arcs and shaved arcs. |

| Sliver | Reports on slivers between lines and pads & between pads and pads. Slivers between a text feature & a functional pad will be reported, while silver between two features with the Copper Text attribute will be ignored. |

| Stubs | Reports unconnected line endpoints. |

Power/Ground Checks:

The Power/Ground Checks are intended to find potential manufacturability defects in power, ground and mixed layers. It uses different algorithms to diagnose negative and positive power and ground layers. The main checklist is displayed in this table.

| Check Items | Functions |

| Drill | Reports distance violation between NPTHs/PTHs/Vias to plane, copper, clearance and annular rings. |

| Silver | Reports slivers in negative and positive layers. |

| Route | Reports close spacing between copper/clearance and route features |

| Thermal | Reports spoke (tie) widths and reduction of connectivity of thermal pads. |

| NFP Spacing | Reports spacing between NFPs and NFPs, NFPs and planes. |

| Plane spacing | Reports spacing between features of different planes |

| Keepin/ Keepout areas | Reports features inside/outside Keepin/Keepout areas |

| Plane width | Reports insufficient width of copper between 2 drills connected to a copper plane. |

| Plane connection | Reports disconnected areas of copper often used as reference planes that are left in a design could cause an unreferenced critical net, or a missing electrical connection. |

Solder Mask Checks:

This function checks Solder Mask layers for potential manufacturability defects. Solder Mask layers are always assumed to be negative, that is, all positive features describe clearance or the absence of solder masks. This action also checks if solder paste has been deposited on all SMD pads. The action operates on a single Solder Mask layer per side at a time. If more than one SMD is selected, the action will not work. The main checklist is displayed in the following table.

| Check Items | Functions |

| Drill | Reports close distance to solder mask openings of PTH/NPTH annular rings, and where NPTH touches mask.. |

| Pads | Reports close distance to solder mask openings of all pads, including undrilled pads. It also reports on a special group, Gaskets, which reports the width of solder mask overlap on features. |

| Coverage | Reports lines too close to clearance (that is, not adequately covered). |

| Route | Reports close distance between solder mask and route features. |

| Bridge | Reports different net pads without solder mask bridges. |

| Silver | Reports slivers between solder mask clearance. |

| Missing | Reports missing clearances. |

| Spacing | Reports close spacing between clearance (wider than silver). |

| Extra | Reports solder mask features which lack copper pads, or do not intersect with copper. |

Silkscreen Checks:

This function is intended to find potential manufacturing defects in silkscreen layers and generate statistics. The check operates only on silk screen layers as it relies on the job matrix to find related external copper, solder mask and drill layers against which to check. The main checklist is displayed in this table.

| Check Items | Functions |

| Solder mask clearance | Reports close distances between silkscreen features and solder mask clearance. |

| SMD clearance | Reports close distances between silkscreen features and SMD pads. |

| Pad clearance | Reports close distances between silkscreen features and pads. |

| Hole clearance | Reports close distances between silkscreen features and drills. |

| Route clearance | Reports close distances between silkscreen features and route features. |

| Line width | Reports line width violations and length to width ratio violations. |

| String overlap | Reports the touching or intersection of silkscreen features of various string value. |

Quality Control

Being aware of the importance of time and accuracy to you, we are commiting ourselves to double confirming your circuit design file before PCB manufacturing and quickly discussing with you when there’s any concern or questions on your printed circuit boards during production.

Although Free DFM & DFA check will be applied before circuit boards assembly, possible issues might occur during the PCB assembly process. In order to save you time and increase correctness of your mass products at a low cost, we offer first article inspection and approval service.

First Article Inspection (FAI)

FAI is carried out on first one of two completed boards prior to volume production so that errors can be found, modified and stopped from flooding among mass products timely.

Owing to inspection capabilities with the application of flying probe, AOI (Automated Optical Inspection) and AXI (Automated X-ray Inspection), our inspection items range from materials, technologies, manufacturing, quality to equipment. Detailed items are listed below:

• Materials

- 1). Quantity

- 2). Quality

• Technologies

- 1). SMT procedure

- 2). Stencils

- 3). Polarity

- 4). Soldering

- 5). Solder joints

• Manufacturing

- 1). Printing

- 2). Placement

- 3). Reflow soldering

- 4). PTH placement

• Quality

- 1). Package

• Equipment

- 1).Printing and mounting station

Once FAI is finished, we’ll provide corresponding inspection report for first article circuit board. Our engineers will come up with suggestions on how to deal with errors so as to make sure your PCB design characteristics can totally comply with the performance of products and projects.

First Article Approval:

Once first article circuit board comes out, you have 2 options to implement their first article approval:

Option 1: For basic check and inspection, we can email you images of first article board.

Option 2: If you require more accurate inspection, we can ship the first article board to you so that you can carry out inspection in your own workshop.

No matter which method for approval, it is a good idea that you come up with first article inspection requirement during quotation to save time and increase efficiency. Moreover, our engineers will surely make timely adjustments so as to ensure the remaining build time and quality of products.

Automated X-ray Inspection

Vayu will strive for providing high-quality PCB manufacturing and assembly for clients from all over the world at competitive prices since our establishment. Due to the development of Surface Mount Technology and increasing complexities of electronic products, high-density and small PCBs account for the majority. As a main form of structural test and inspection, Automated Optical Inspection is only applicable for defects that are relatively easier found such as open circuits, solder bridges, solder shorts, insufficient solder and excess solder. However, because pins of BGAs are hidden under the chip package, it’s difficult to test them only based on light. That’s why Automated X-ray Inspection (AXI) is required.

Belonging to the same structural test and inspection category, AXI shares the same principle with AOI, that is, inspection is carried out through capturing images. The difference between them lies in the source in that AOI depends on light source to capture images while AXI on X-ray. Materials absorb X rays according to their atomic weight proportion. Materials made of heavy elements get more X rays absorbed while those made of light elements get fewer. As a result, materials absorbing more X rays are displayed more obvious or darker in their images than those absorbing fewer rays. When it comes to PCBA, solder joints are made of materials with heavy elements while other parts such as most packages, silicon ICs and component leads are made of materials with light elements. Therefore, high-quality solder joints should look darker or more obvious on images than other parts.

Based on its working principles and capabilities, AXI is applied to test PCB printed circuit boards containing components with array-style packaging or fine pitch packaging including BGAs, CGAs (Column Grid Arrays), CSPs (Chip Size Package), etc. AXI is usually placed in the assembly process, just after the last soldering no matter wave soldering or reflow soldering. Furthermore, Automatic X-ray Inspection is usually applied coupled with boundary scan test, ICT and functional test in order to obtain optimal inspection results.

AXI features some advantages as a type of structural test and inspection:

• Some defects can be found in the early stage of printed circuit board assembly process;

• It is contributive to the cost reduction of defects;

• It stops defects from flooding among remaining PCB assembly or even clients’ practical projects.

AXI equipment is classified into two categories: 2D and 3D equipment. For 2D AXI equipment, Vayu uses model VIEWX2000, responsible for inspecting PCBA manufacturing defects including opens, shorts, insufficient solder, excessive solder, missing electrical parts, misaligned components, solder voiding etc.

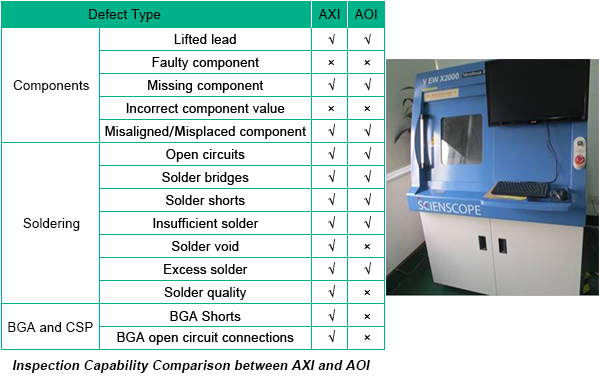

Although AXI and AOI have the same working principles and play similar roles in PCB assembly production line, defects they can detect differ to some extent. The following table shows comparison between AXI and AOI in terms of their inspection coverage.

Vayu carries out X-ray inspection on assembled circuit boards to guarantee the qualifty of our assembly work.

Automated Optical Inspection

AOI, short for Automated Optical Inspection / Automatic Optical Inspection, is well responsible for quality control in terms of both Printed Circuit Board (PCB) fabrication and PCB Assembly (PCBA).

Necessity of AOI Test:

It’s almost impossible for current electronic devices to work without a circuit board. A PCB plays a critical role in electrical connection between components such as integrated circuits (ICs) that are assembled on bare boards applied in different electronic devices ranging from relatively simple equipment such as electronic watches, calculators, handheld computers, electronic communication equipment to advanced electronic devices like military, medical or aerospace products.

Due to the rapid progress of modern technologies and people’s continuous higher demands for electronic devices, modern circuits have to be much more complicated than what they were just a few years ago. Furthermore, the introduction of Surface Mount Technology (SMT) leads circuit boards to develop towards miniaturization and high density. Nowadays, even an ordinary printed circuit board contains lots of solder joints and layers. Moreover, component size keeps gradually shrinking so that the massive application of 0402 and 0201 components leads to urgent necessity to ensure that correct components are applied with correct polarity and values.

When it comes to inspection methods for PCBs and PCBAs, manual inspection did make sense for a period of time. Nevertheless, it is hardly accepted for inspection of modern circuit boards since it fails to inspect their internal issues or defects.

Current market strongly calls for a reliable and fast inspection method, which is why AOI (Automated Optical Inspection) becomes so significantly important before products leave manufacturing house and function in customers’ projects or devices. Moreover, AOI test enables a reduction of cost and to make issues exposed in the early phase.

Attributes and Capabilities of AOI Test:

Depending on visual methods, AOI test can be applied to detect a lot of surface defects including scratches, nodules, stains, opens, shorts, insufficient or excessive solder, incorrect components, missing components, incorrect polarity of components etc. As a matter of fact, these defects AOI is capable of going through belong to items of manual visual inspection that was mainly applied prior to the popularity of AOI inspection which is, however, capable of performing them quickly and accurately.

• Multiple inspection objects – AOI test works perfectly for both bare PCBs and PCBAs. For PCB inspection, defects are checked such as shorts, opens and insufficient solder. For PCBA inspection, issues are inspected including component soldering, polarity and values.

• Flexibility – Automated Optical Inspection can be arranged in any stage of manufacturing line in accordance customers’ needs and cost tolerance capacity. In order to increase inspection efficiency and reduce corresponding cost, it’s optimal to place it after reflow soldering because most defects result from nonconformance occurring during soldering process. The flexibility attribute of AOI test leads to reduction of cost since it is an in-process test and as soon as issues are discovered, manufacturing or assembly parameters can be instantly modified so that later products will be correctly produced. As a result, more products won’t be rejected during functional test or final inspection.

• Low cost – Compared with Automated X-ray Inspection (AXI), post-reflow AOI is less expensive when it comes to solder joint defects inspection including bridges, broken joints, dry joints etc.

• Accuracy and Reliability

Working Principle of AOI Test:

AOI test achieves its inspection process by scanning board surface. Depending on one or more high-definition cameras, this equipment can capture images of PCB surface with the help of numerous light sources including fluorescent lighting, LED lighting or infra-red or ultra-violet lighting. Then, comparison will be made between the captured image and board parameters that have been input into computer in advance so that differences, abnormalities or even errors can be clearly indicated by its built-in processing software. The whole process can be monitored at any second.

The analysis whether a board is perfect or features issues can be drawn by different algorithms applied by AOI. When it comes to simple applications inspection, pixel-counting algorithm is used containing the following methods.

• Template matching – Template-matching method, also called area-based method or correlation-like method, has been popular for a couple of decades. Based on pixel-by-pixel method, a small template is applied to a large inspection image through sliding template window. Then, normalized cross correlation (NCC) will be calculated between the template and inspection image. The larger the value of NCC is, the higher matching between them will be.

• Object recognition – Object recognition conforms to the same principle as view method in that difference is observed through comparison between an ideal image and the captured image of an object.

• Blob analysis – Blob analysis refers to a process during which the object is separated from the background first. Then with a pixel-based image applied, a blob is generated through grouping of object pixels to inspect issues of objects.

Owing to the progress of technologies and higher demand from market for efficiency and effectiveness, some new methods start to play a major role in PCB or PCBA inspection, among which vectoral imaging technology stands out.

As a pattern location search technology, vectoral imaging is based on geometric feature extraction instead of complete grey scale pixel values. Under such circumstances, the image analysis is not influenced by color changes or non-liner changes. Furthermore, vectoral imaging performs better in reduction of false failures due to the attribute of background elimination.

AOI Test from Vayu:

As a primary testing technique in PCB assembly, AOI applies to fast and accurate inspection of errors or defects occurring in PCB assembly process so that high quality of PCB assemblies can be ensured with no defects after their leaving assembly line. AOI can be applied both to bare PCBs and PCB assembly. In Vayu , however, it is mainly applied to inspect SMT assembly line and for testing of bare circuit boards, bed of nail and flying probe are used instead.

Professional Automated Optical Inspection machine of Vayu is applied with its model ALD515.

Vayu provides both online and offline AOI test to meet clients’ different demands. Online AOI test features a higher degree of automation with no need of manual operation whereas offline AOI test features a lower degree of automation with the need of manual operation. Nevertheless, both of them share the same inspection principles, inspection objects and inspection methods.